Hot rolling mill is a steel rolling equipment for producing hot rolled coil. Hot rolling mill usually includes: step continuous heating furnace, high pressure water descaling, four-high reversible roughing mill with vertical roll, flying shear, finishing mill group composed of six four-high mills arranged in series, coiler, laminar-flow cooling device, finished product collection equipment and various transportation rollers. Billet by heating the introduction, get rid of the iron oxide by high pressure water descaling, breakdown into the four-roll reversing roughing mill, rolling into a suitable for continuous rolling process sufficiently neutral in the middle of the block to ensure that the steel plate width, middle slab after flying camber of the head, into the dissertation. A rolling into the required specifications, finally by the coiler winding. During the rolling process, high pressure water is used for secondary descaling of steel plates in both rough and finishing mills. Hot tandem mill sets usually adopt full line automatic control, and adopt hydraulic AGC thickness automatic control, strong roll bending system, rapid roll changing and other new technologies.

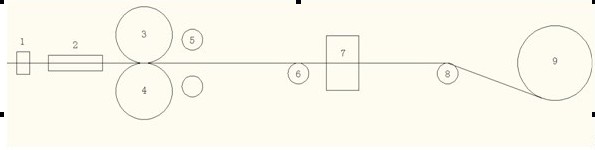

The main work of the aluminum continuous casting and casting mill of xuanlong steel co., LTD., fengrun district, tangshan city, is to roll the high-temperature molten steel melted by the original furnace and refined by the static furnace into steel plates while cooling down rapidly, and finally roll into steel coils through the coiler. The equipment mainly includes main rolling mill, steel level control device, titanium wire feed, casting nozzle trolley, graphite spraying and walking, translation hydraulic shear, coiler, unloader, etc., as shown in the figure.

The rolling speed is 2.0m/min, the roll weight is 5000kg, the roll diameter is 610 ~ 1920mm, the plate width is 1400mm, the plate thickness is 6 ~ 8mm, and the motor of up and down roll is 90kW. In view of the technological characteristics of the complete set of electric control system of casting and rolling mill (long-term stable continuous production, once the accident will cause serious losses), the key to meet the control requirements is to choose a high performance, high reliability system control inverter. Requirements: speed control for lower roll, torque control for upper roll, and inverter control. After a comprehensive analysis of the control system, the decision to use ambition letter AMB600 series inverter transformation.

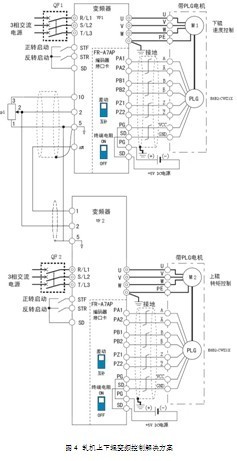

Hardware wiring diagram of frequency converter of tandem mill

The hardware wiring diagram of the inverter in tandem mill is shown in the figure. The speed setting of VF1 down-roll converter adopts potentiometer, and PLG differential input signal is connected as feedback signal of closed-loop vector control. The jumper setting is shown in figure 4. Meanwhile, torque signal is output to VF2 inverter. The VF2 up-roll converter adopts torque control, whose torque command comes from the output of VF1, and the speed limit comes from the speed of VF1.

AMB600 series inverter performance parameters

Control mode: open loop vector control (SVC), V/F control, closed loop vector (VC), open loop torque control, position loop control

Starting torque: 0.5hz /150%

Speed adjustment range: 1:100 (SVC), 1:1000 (VC)

Accuracy of steady speed: ±0.5% (SVC), ±0.05% (VS)

Voltage class: 220V, 380V, 690V, 1140V

Super power driving technology: single 380V, 680Kw, and 2000Kw

Before and after the use of the converter transformation, the system function changes greatly, compared with the system performance before the transformation, the system after the transformation with high precision speed control, torque control, fully meet the steel plate high precision, high torque industrial requirements. At the same time, the stability and reliability of the system are realized.

Ambition letter AMB600 has the vector control method of speed sensor, mainly used for high precision speed control, torque control, simple servo control and other applications that require strict control performance. The speed sensor used in this mode is generally a rotary encoder and is mounted on the shaft end of the motor under control. In the continuous casting mill, two high precision closed-loop vector anbunxin AMB600 inverter is used for control, which solves the industrial requirements of high precision and high torque of steel plate.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

amb@ambition.com.cn amb@ambition.com.cn |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|